Identifying & Fixing the Porsche IMS Bearing Problem

Porsche IMS Bearing Problems (And How To Fix Them)

The Porsche IMS bearing issue is well known among owners, enthusiasts, and mechanics. Porsche models from 1997 through 2008 including the 911, 996, and 997 as well as the Boxster, Cayman, 986, and 987 have all experienced the Porsche IMS bearing problem. This issue can cause a catastrophic engine failure and lead to very expensive repairs. LN Engineering wants to prevent that from happening to you by allowing the Porsche IMS Bearing to be replaced as part of regular schedule maintenance.

In this blog we're covering:

- The design and purpose of an IMS bearing

- Causes of the IMS bearing issue

- Symptoms of an IMS bearing failure

- Solutions for the Porsche IMS bearing problem

Design and Purpose of the Porsche IMS bearing

IMS is an abbreviation for intermediate shaft. For decades, Porsche has used an intermediate shaft in all overhead-cam horizontally-opposed engines to drive the camshafts. The best known example of this is the Mezger engine, whose IMS used oil pressure fed plain bearings on either end to support the intermediate shaft. The intermediate shaft is connected to the crankshaft by chains. Another set of chains connect the camshafts to the intermediate shaft. In doing so, the IMS indirectly moves the camshafts off the crankshaft.

Beginning in 1997 with the introduction of the Boxster and in 1999 with the 911 (996), Porsche changed the intermediate shaft to use a sealed ball bearing on the end closest to the flywheel. In lieu of a plain bearing, the ball bearing provided both axial and lateral support for the intermediate shaft in the M96 and later, in the M97 engine. Any Porsche 911 or Boxster model assembled between 1997 and 2005 may be subject to the Porsche IMS bearing issue, but in these models, the IMS bearing is easily replaced. Early models used a stronger dual row sealed ball bearing which was replaced starting in model year 2000 with a weaker, sealed single row ball bearing which had a much higher failure rate and was the subject of the Eisen class action lawsuit settled by Porsche.

With late 2005 and all 2006 through 2008 model Porsche 911 (997) as well as Boxster and Cayman 987 models, Porsche utilized a larger, non-serviceable IMS bearing that unfortunately cannot be replaced without complete engine disassembly. Replacement engines manufactured in or after late 2005 will also have a non-serviceable intermediate shaft bearing.

What Causes the IMS Bearing to Fail?

The exact cause of the Porsche IMS bearing failure issue is not known. However, some variables that may contribute to IMS bearing deterioration include:

The exact cause of the Porsche IMS bearing failure issue is not known. However, some variables that may contribute to IMS bearing deterioration include:

- Insufficient load capacity

- Poor lubrication

- Extended oil drain intervals

- Manufacturing quality issues

- Elevated engine temperatures

- Lack of factory recommended service interval

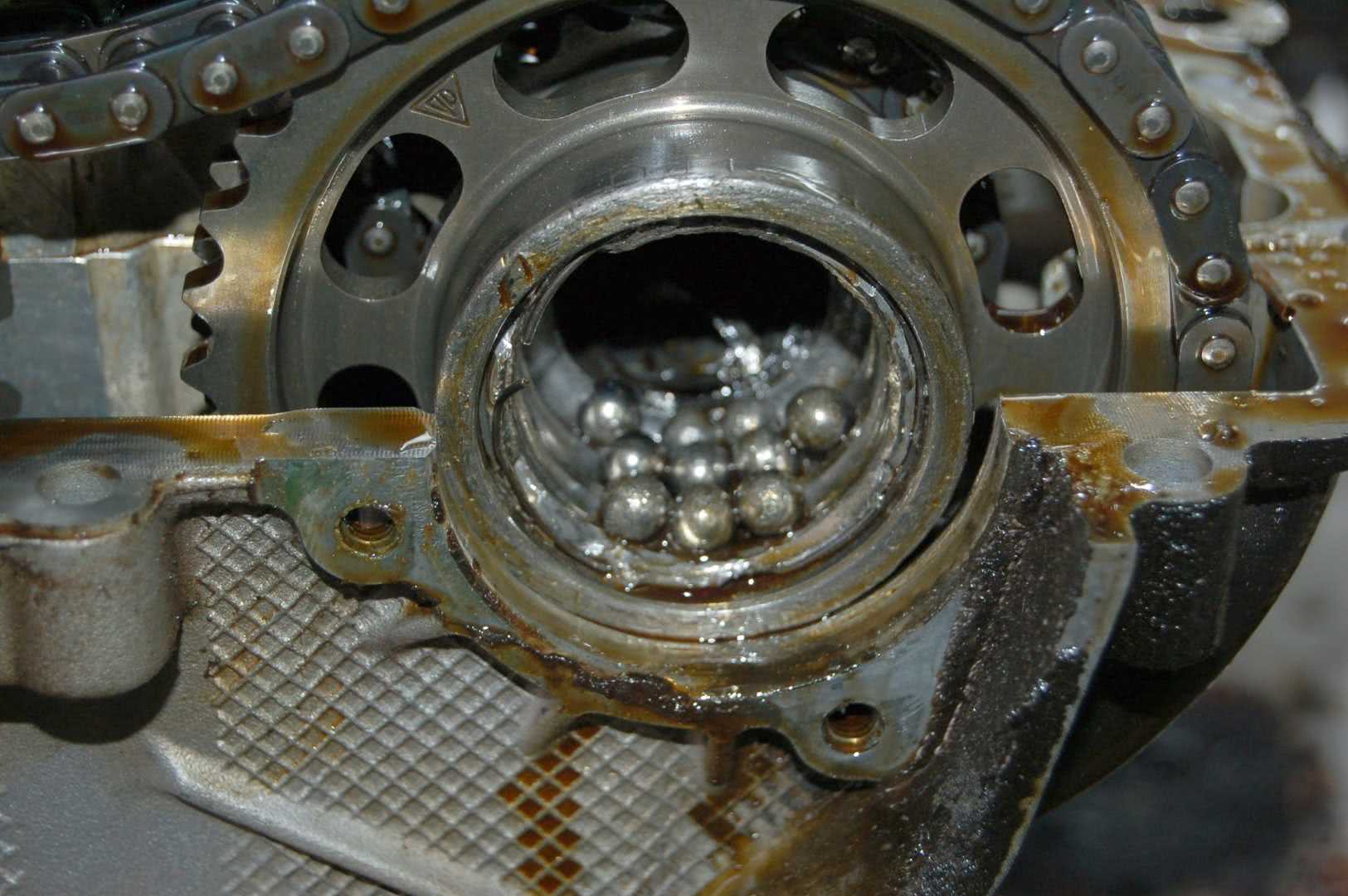

Failure rates under warranty for the single row IMS bearing used from 2000-2005 is reported to be as high as 10%. Out of warranty, the failure rate is suspected to be significantly higher. When the IMS bearing fails, there is a loss of camshaft timing resulting in bent valves and significant foreign object debris that can cause widespread engine damage. The engine must be completely disassembled to replace the intermediate shaft and correct any collateral damage caused by the IMS bearing failure. All IMS bearings will eventually fail if not changed as out as part of preventative maintenance like a timing belt on most modern engines which has to be changed based on time or mileage, whichever limit is reached first. Cars that sit, are infrequently driven, or drive short distances are most likely to have a failure.

Symptoms of a Porsche IMS Bearing Failure

The Porsche IMS bearing problem results in irrevocable damage and complete engine failure. While the grease seal on the ball bearing remains intact, any debris from a worn IMS bearing will remain contained within the intermediate shaft bearing. However, once the seal is compromised, particulate matter can exit the bearing and contaminate the engine oil. Once you find IMS wear debris in your oil filter, your IMS bearing has already started to fail, and you may have already damaged your Porsche engine.

However, just because you don't find debris in your oil filter doesn't mean there aren't any issues. You may have an IMS bearing problem without knowing it, and you won't know it until your engine fails. At that point, you'll have to replace it completely, which can be extremely costly. It is common for an engine with the factory single row IMS bearing to fail without warning without any prior symptoms such as debris in the oil filter.

Earlier dual row bearings, due to their higher load capacity and two rows of ball bearings, can start generating debris or even make noise, announcing a problem well in advance of catastrophic failure. This too can pose a problem as the IMS can generate significant wear material causing damage to other engine components during continued engine operation while symptoms are present but a complete intermediate shaft bearing failure has not yet occurred.

Solutions for the Porsche IMS Bearing Problem

There are effective solutions to the Porsche IMS bearing problem, like our Classic Dual Row and patented Single Row Pro IMS Retrofit Kits, which are designed to be installed as preventative maintenance for 1997-2005 Porsche Boxster and 911 (996) engines. Introduced in 2008, the IMS Retrofit replaces the factory sealed ball bearing with a dual row ceramic-hybrid ball bearing. This bearing omits grease seals and allows for engine oil to cool and lubricate the bearing. As the intermediate shaft is submerged in engine oil during normal operation, forced oiling is no required for the IMS Retrofit bearing.

In addition, LN Engineering also offers the RND RS Roller IMS Retrofit which uses a cylindrical roller bearing for those who prefer this over a ball bearing.

Lastly, LN Engineering also developed and patented the IMS Solution that eliminates the ball bearing and replaces it with an oil pressure fed plain bearing. Unlike the ball or roller bearings, the IMS Solution provides a permanent solution to IMS bearing problems and requires no future servicing. As of 2021, over 43,000 Porsche owners have saved their cars from IMS bearing failure with LN Engineering's IMS bearing replacement kits.

Not sure which IMS solution is right for you or who to have replace your Porsche's intermediate shaft bearing? Get more info about LN Engineering solutions to identify and fix the Porsche IMS bearing problem.

Contact our team to help avoid Porsche IMS Bearing Failures today!